Perforated Cable Tray Manufacturers in India – Evolution Enterprises

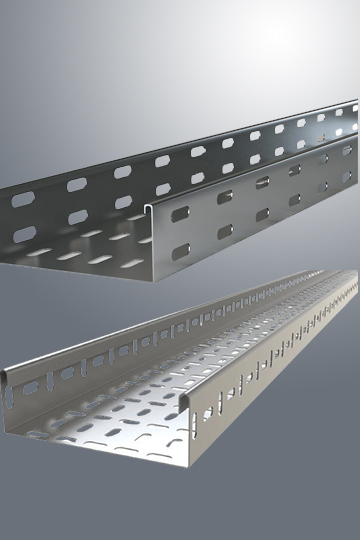

Evolution Enterprises, one of the dominant perforated cable tray manufacturers, dealers, and wholesalers in India. We are offering new and modern types of perforated cable trays that have multiple types of punched holes in them and allow for ventilation and protection of cables.

These are highly used in industrial facilities, commercial buildings, data centers, power plants, wind farms, and solar installations also. This structure of ventilation allows cables to prevent any kind of overheating and maintains the longer performance over time. Below we have mentioned its various types, its benefits, and its applications.

Types of our Perforated Cable Tray

Being one of the best perforated cable tray dealers and wholesalers in India, we are offering various types of cable trays that give maximum performance. Here we have listed some types, such as:

- Stainless Steel (S.S.) Cable Tray: In this cable tray, we have used a strong and pure form of stainless steel for improving the durability of the tray. This steel is resistant to corrosion and has high aesthetic quality. These stainless steel cable trays have the highest aesthetic appeal and polished appearance over time. Due to its qualities, these are highly used in food and pharmaceutical industries, marine and offshore, and clean rooms.

- Aluminum Cable Tray: These trays are lightweight in nature due to aluminum, and it is highly resistant to corrosion. The aluminum in these trays keeps a balance between strength, ease of installation, and cost efficiency. Our trays are fully recyclable, and it is a sustainable option for environmentally conscious projects. These are highly used in commercial buildings, power distribution, and renewable energy projects.

- Mild Steel (MS) Cable Tray: In these trays, we have used strong quality of mild steel or galvanized steel and coated it with a protective layer. These trays are commonly used in industrial settings where cost-effectiveness and higher strength are required. Our MS cable tray has a higher load-bearing capacity, making it ideal for use in industrial environments with large power cables. In construction sites, these trays are majorly used due to their route handling capacity.

- Galvanized Iron (GI) Pregalvanized Cable Tray: These trays are made from steel that is coated with a special type of layer of zinc through the process of the pre-galvanized process. This coating is more helpful to resist against rust and corrosion. Our GI pregalvanized cable trays are the most cost-effective and cheaper than stainless steel and aluminum. These trays are preferable for using in outdoor installations, industrial and commercial use and water treatment plants also.

Technical specifications

We have given below a technical sheet of our perforated cable tray which gives you more detailed technical information:

| Specification | Stainless Steel (S.S.) Cable Tray | Aluminium Cable Tray | Mild Steel (MS) Cable Tray | Galvanized Iron (GI) Pregalvanized Cable Tray |

|---|---|---|---|---|

| Material | Stainless Steel (304/316 grades) | Aluminium Alloy (Grade 6063) | Mild Steel (Hot Rolled/Cold Rolled) | Galvanized Iron (Pre-Galvanized Steel Sheet) |

| Thickness of Tray | 1.5mm to 3mm | 1.5mm to 2mm | 1.6mm to 3mm | 1.5mm to 2.5mm |

| Tray Width (mm) | 100mm to 1200mm | 100mm to 1000mm | 100mm to 1200mm | 100mm to 1200mm |

| Tray Height (mm) | 50mm to 100mm | 50mm to 80mm | 50mm to 100mm | 50mm to 100mm |

| Load Capacity (kg/m) | 100 to 1000+ kg/m | 50 to 500 kg/m | 150 to 1000+ kg/m | 80 to 800+ kg/m |

| Temperature Resistance | -100°C to 800°C | -50°C to 100°C | -20°C to 100°C | -20°C to 200°C |

| Corrosion Resistance | Excellent (due to stainless steel alloy) | Good (natural oxide layer) | Moderate (may rust over time if untreated) | Good (due to galvanization process) |

| Weight (kg/m) | 6 to 20 kg/m | 3 to 8 kg/m | 6 to 18 kg/m | 5 to 15 kg/m |

| Strength (MPa) | 515 (304 SS), 580 (316 SS) | 215 MPa (6063 Alloy) | 250 MPa to 420 MPa | 270 MPa to 350 MPa |

| Flexibility (Modulus of Elasticity) | 193 GPa | 69 GPa | 210 GPa | 210 GPa |

| Electrical Conductivity | 1.2 x 10⁶ S/m | 35.5 x 10⁶ S/m | 4.7 x 10⁶ S/m | 4.7 x 10⁶ S/m |

| Durability | Very High | Medium | High | Medium to High |

Features of Perforated Cable Tray

As a former perforated cable tray manufacturers in India, these trays are made with the latest technological trends and are highly used in a multiple list of applications. Here we have listed some new features:

- Perforation Pattern These trays have holes or slots to allow air circulation, reducing heat buildup around cables.

- Material Options Our perforated cable tray is available in various materials like steel, aluminum, and stainless steel for different environmental conditions.

- Load Capacity These are specially designed to support different weights of cables, ensuring safety and stability under various conditions.

- Corrosion Resistance All types of cable trays are coated or made from materials resistant to rust, ensuring longevity in humid or corrosive environments.

- Easy Installation Typically features a lightweight design and modular components, allowing for quick and simple setup.

Benefits of our Perforated Cable Tray

Being the best perforated cable tray wholesalers in India, all our types of trays have the maximum features and give benefits such as:

- Improved Airflow These perforated trays allow better ventilation, reducing the risk of cable overheating and ensuring efficient operation.

- Enhanced Cable Protection The tray provides a secure environment for cables, protecting them from physical damage and external elements.

- Easy Maintenance The design allows easy access to cables for inspection, maintenance, and modifications without major disassembly.

- Cost-Effective Our perforated cable trays are less expensive than solid trays, making it a budget-friendly option for cable management.

- Weight Reduction Perforated design reduces the overall weight of the tray while maintaining strength, making it easier to handle and install.

Applications of our Perforated Cable Tray

One of the best perforated cable tray dealers in India, these all types of trays are majorly used in multiple types of applications due to their working mechanism. Here we have listed some applications such as

- Electrical Wiring Systems: Thee trays are highly used to support and organize electrical cables in commercial and industrial buildings.

- Data Centers: It helps in organizing and routing network cables while providing easy access for maintenance.

- Power Distribution: This tray gives proper cable management for efficient power transmission in large facilities.

- Telecommunication: These are highly used in telecommunication facilities for supporting cables and wires.

- Control Systems: Our trays are ideal for use in manufacturing plants and automated systems.

- HVAC Systems: Supports cables for heating, ventilation, and air conditioning control systems.

- Industrial Applications: Provides cable management in heavy industries where cables require protection from environmental conditions.

- Oil & Gas Plants: Our trays are used in hazardous and high-risk areas for cable routing and management.

One of the leading perforated cable tray manufacturers, dealers, and wholesalers in India, we at Evolution Enterprises are providing the best perforated cable trays that are commonly used for improving the mechanism of the cables and enhancing the air circulation to prevent overheating. We have used strong quality materials in these trays to improve their durability. Contact us today for more information!