Laser Cutting Services

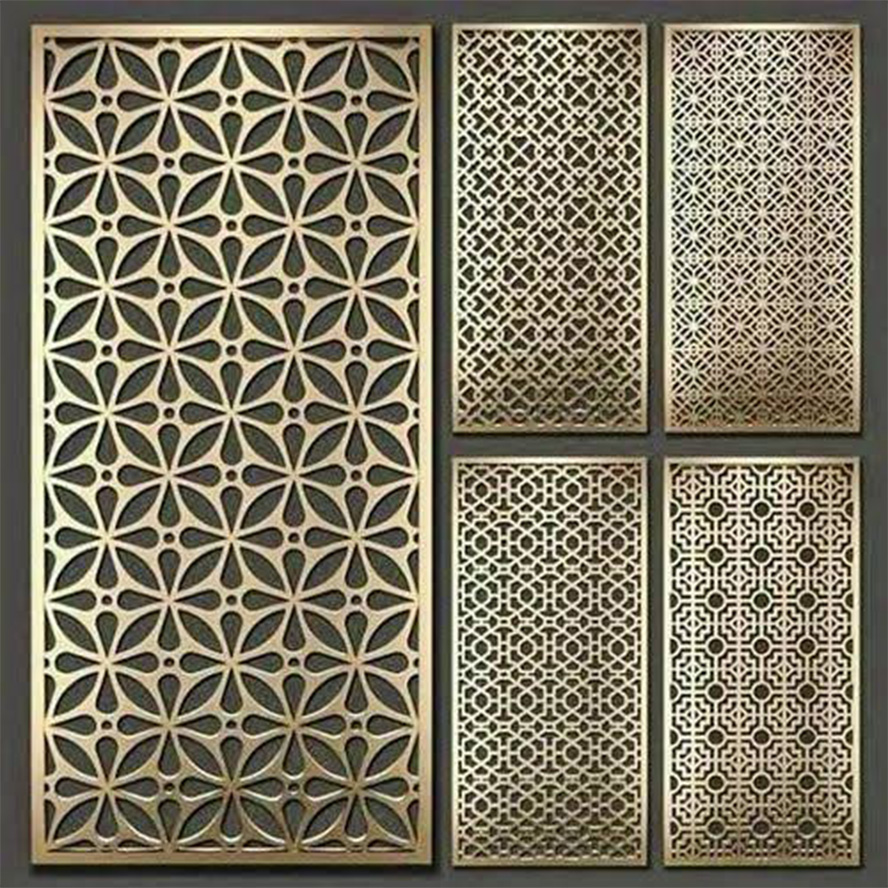

Laser cutting offers possibilities for completely new product designs. Innovative and complicated shapes are easy to achieve with the laser and can make a product stronger or aesthetically better without sacrificing strength.

Simple programming from a computer aided design drawing makes it possible to quickly program a part for laser cutting, even when it comes to small series production or prototyping.

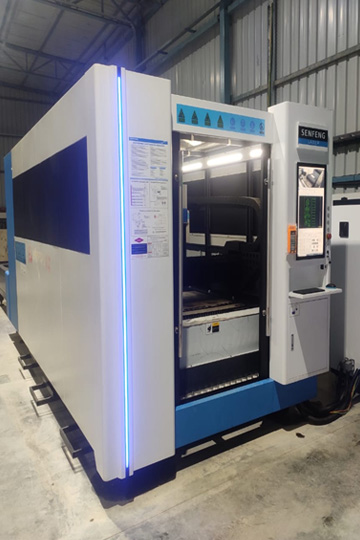

Laser cutting machine is a power efficient machine that finds extensive application in metal fabrication and industrial application.

Laser cutting machine is featured with superior functioning , noise less operation and low maintenance.

Machine Specification

| MODEL | : SF3015H |

|---|---|

| WORKING AREA | : 3050 X 1530 |

| WORKING TABLE | : 2 |

| LASER CUTTING CAPABLITY | |

| M.S. | : 0.5 TO 20 MM |

| S.S. | : 0.5 TO 10 MM |

| ALLUMINIUM | : 0.5 TO 08 MM |

| G.I . | : 0.5 TO 06 MM |

Specification Of 3 KW Laser Machine

-

-

Laser source of 3 KW capacity

-

Laser cutting capability of

M.S. : 0.5 TO 20 mm

M.S. : 0.5 TO 10 mm

ALL : 0.5 TO 8 mm

G.I. : 0.5 TO 6 mm

-

Two changeable work table, time saving and efficinet

-

Various work area can cut small to large plate

Application Of Laser Cutting Machine

-

Sheet Metal Processing : Fiber laser cutting machine is born to process metal sheets and pipes in modern metal processing industries where precision and productivity are increasingly required. fiber laser cutters have shown reliable and highly efficient cutting performance.

-

Automobile Industry : Laser Cutting is a key Tool in the Automotive industry, Used in making Variety of Parts and components For Automobile Body Panels, chassis and frames, Interior Components, Exhaust System, Electrical Systems, Engine parts etc.

Due to its Various Advantages like Precision, Efficiency and Rapid Prototyping. -

Decoration Industry : Many complex graphics can be quickly processed by efficient fiber laser cutting system and the cutting results have won the favor of decoration companies.

Sheet Metal Processing

Fiber laser cutting machine is born to process metal sheets and pipes in modern metal processing industries where precision and productivity are increasingly required. fiber laser cutters have shown reliable and highly efficient cutting performance.

Automobile Industry

Laser Cutting is a key Tool in the Automotive industry, Used in making Variety of Parts and components For Automobile Body Panels, chassis and frames, Interior Components, Exhaust System, Electrical Systems, Engine parts etc.

Due to its Various Advantages like Precision, Efficiency and Rapid Prototyping.

Decoration Industry

Many complex graphics can be quickly processed by efficient fiber laser cutting system and the cutting results have won the favor of decoration companies.

Industrial Product

3 KW Laser Machine.

-

3 KW double pallet closed body with automatic changeover of size 1500 x 3000 mm.

-

Laser source of 3 KW capacity

-

Laser cutting capability of

M.S. : 0.5 TO 20 mm

M.S. : 0.5 TO 10 mm

ALL : 0.5 TO 8 mm

G.I. : 0.5 TO 6 mm

-

Two changeable work table, time saving and efficinet

-

Various work area can cut small to large plate